Sterilization

Our process starts with Cavicide. A convenient, ready-to-use surface disinfectant that is effective against many harmful organisms like Mycobacterium, Fungi, Enveloped Viruses & Multidrug-Resistant Bacteria. We use this disinfectant to wipe down some of our Instruments and equipment.

Our Next step would be to run those instruments through our UltraSonic. Ultrasonic cleaning uses high-frequency, high-intensity sound waves in a liquid to facilitate or enhance the removal of foreign contaminants from surfaces submerged in an ultrasonically activated liquid.

Once those instruments come out of the UltraSonic then the next step for them would be to get bagged in individual pouches. These pouches let instruments wrapped in them get sterilized and keep them sterilized. These steam sterilization pouches are also environmentally friendly.

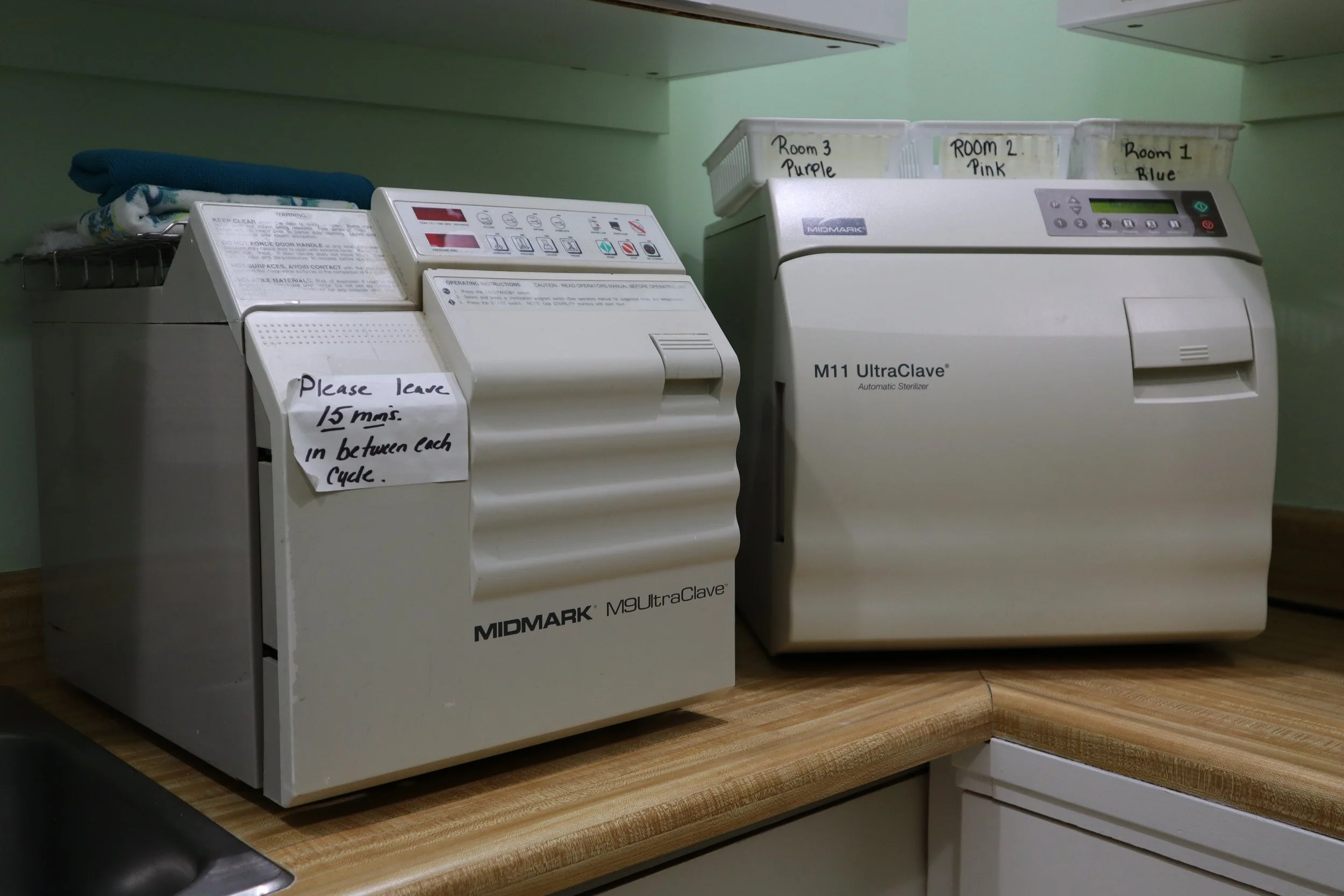

The last step would be to run those pouches through our UltraClave’s. The purpose of an UltraClave is to use steam under pressure to kill harmful bacteria, viruses, fungi, and spores on items that are placed inside a pressure vessel. The items are heated to an appropriate temperature and come out sterilized.

We sanitize other items to make sure they are nice and clean!

Since we have a washer and dryer on site, we also wash and clean our jackets, micro towels & shoe covers with hot water and heat to make sure they are nice and clean for every patient.